Our Helical/Spur Gear Capabilities

- Diameter: Max 120”

- Diametral Pitch: Min 32 DP, Max 1.0 DP

- Module: Max 24

- Gear Finishing Methods: Hob/Shaper cut, Shave, Grind

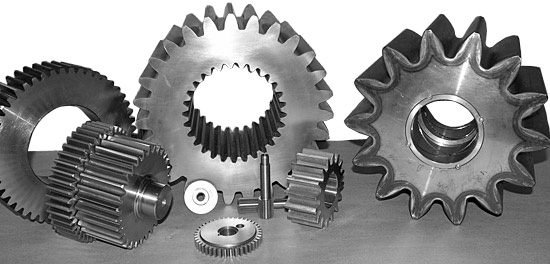

Spurs & Helicals

Circle Gear, from day one, has been providing the industry with spurs and helicals. Using ultra reliable mid-twentieth century equipment, every bit of our 7500 sq. ft. “Job Shop” was utilized to make gears with outstanding quality. Fast forward today, to our 122,000 sq ft multi–building facility with the newest 21st century technology including robotic part loading. Only with dedication, technical know-how, and the ability to exceed customer demands could our little “Job shop” grow to be the industry leader it has become today.

Equipped for Success

Over the years we have built an impressive inventory of gear cutting tools that covers a wide range of gears types:

- Diametral Pitch, Module, Circular Pitch

- Standard Depth

- Stub Depth

- Involute Spline

- Transverse

- Pre-Shave

- Pre-Grind

- Sprocket/Silent Chain

- Timing Belt

Our Sales and Engineering department will work with you to make sure your project is processed with the tool that best meets your application.

At Circle Gear & Machine Co., we are a full-fledged machining and manufacturing facility with the capability to produce custom spur and helical gears with an impressive range of sizes and diameters. Thanks to the versatility of our equipment, it’s not uncommon to see a cart full of 1” diameter parts placed next to a pallet with a 120” diameter gear.

Obviously, gear teeth are just one feature of a gear. We provide all the support to saw, turn, mill and drill, cut, shave, deburr, key, heat treat, hard turn, surface grind, diameter grind, and finally tooth grind. With over a hundred routing operations in our system, we are set up to handle any feature your project may have.

Proven Quality Gears

Quality is easily appraised with our Wenzel Geartec LH87 gearchecker. Charts, along with dimensional reports, can be provided so you can have no doubt your gears will perform as expected. Circle Gear’s (QMS) Quality Management System that is ISO-certified, ensures that from start of contract to shipment of product, every manufacturing step is monitored and traceable.

Whether you are looking for spur, helical-cut including double helical gears, and even gearbox repair, our team can guide you to the best solution. We strive to meet our customers’ objectives, quality, and delivery requirements. Contact our support team or request a quote if you are looking for more information about our gear and gearbox products or services. Our support team is always available to respond to your questions and concerns.

Custom Spur Gears Capabilities

| Diameter | Max 120 Inch |

|

| Diametrical Pitch | Min 32 DP | Max 1.0 DP |

| Module | 24 | |

| Face Width | Max 60 Inch |

|

| General Capabilities | As Needed Contract Just-In-Time | Production Small Parts |

| Primary Capabilities | Die Forming Finishing | Heat Treating Machining |

| Materials | Acetal/Delrin Alloy Steel Aluminum Brass Bronze Carbon Steel Ductile Iron | Gray Cast Iron Nylon Plastic Phenolic Polycarbonate Polyester Stainless Steel |

| Industry Focus | Automotive Biotechnology Chemical Construction Electrical Electronics Food Processing HVAC Heating, Ventilation, and Air Conditioning Machinery Marine | Medical Mining Nuclear Oil, Gas, Petroleum Optical Packaging Pharmaceutical Plumbing Pneumatics Pulp & Paper Pumps Semiconductor |

| Shaft Feature | Flat Hex |

|

| Gear Cutting Method | Broaching Climb Hobbing Conventional Hobbing Flame Cutting | Milling Shaping |

| Gear Forming Method | Centrifugal Casting Die Casting Forging Sand Casting | Sand Casting |

| Gear Finishing Methods | Grinding Honing | Lapping Shaving |

| Heat Treatment Methods | Carburizing Flame | Induction Nitriding |

| Production Volume | Specialty Production Shop Prototype Low Volume Small Run | High Volume Large Run Long Run Large Scale Production Volume Run |